Imagine the power to transform an ordinary object into a unique, personalized item with the simple addition of a custom aluminum nameplate. This guide elucidates the process of creating such nameplates, offering a detailed insight into the myriad of choices available, from shape and size, to material and finish options.

Various layout and corner options are explored to enhance the aesthetic appeal of the product. The guide further delves into the specific custom specifications that can be incorporated to create a truly bespoke nameplate.

An overview of the fabrication processes involved in nameplate manufacturing is provided, along with additional customization options for those seeking the ultimate in personalization. An understanding of these intricate details ensures optimal control in the creation process, guaranteeing a final product that is both functional and visually appealing.

This guide to custom aluminum nameplates is therefore an invaluable resource for those desiring to create a unique and personal product.

The applications for custom aluminum nameplates are multifaceted, spanning across various domains such as equipment and product identification, as well as asset management.

These nameplates serve as a robust tool for distinctly marking and identifying equipment and products, thus facilitating easy tracking and inventory management.

Furthermore, they prove to be indispensable in the realm of asset management, providing a durable, clear, and easily accessible record of essential information.

Understanding equipment and product identification via custom aluminum nameplates plays a crucial role in enhancing safety measures and optimizing the use of machinery in various industrial settings.

These nameplates are essential tools for:

Through these, aluminum nameplates ensure correct identification, usage, and maintenance of equipment, reducing potential mishaps.

The subsequent section will delve further into how this contributes to effective asset management.

Impeccable asset management, a task of monumental importance, stands as the bedrock of operational efficiency, allowing businesses to unlock unprecedented levels of productivity, streamline processes, and dramatically enhance the lifespan of their valuable equipment.

Through the integration of barcoding systems and digitized management, organizations are able to transform their assets into easily tracked items. This reduces the requirement for manual data entry and provides comprehensive insights into operational behaviors.

The adoption of RFID technology further bolsters inventory tracking capabilities, yielding granular visibility into the asset lifecycle. This precise approach to asset management empowers organizations to gain complete control over their resources, thereby ensuring optimal utilization and extending equipment life.

The decision process continues with considering the suitable shape and size for the custom aluminum nameplates.

Selecting the appropriate shape and size for a custom aluminum nameplate is a critical step in achieving a design that aligns with the envisioned aesthetic and functional requirements. Shape significance cannot be understated, as it plays a vital role in determining the overall look and feel of the nameplate. From rectangular to circular shapes, versatile forms are available to suit a variety of design considerations.

Size importance likewise, impacts the visual impact and readability of the nameplate. Smaller dimensions may lend an understated elegance, while larger sizes command attention. Dimension decisions should be made with a thorough understanding of the intended purpose and placement of the nameplate.

| Popular Sizes | Shape Significance | Design Considerations |

|---|---|---|

| 0.75' x 2.5' | Small size for understated elegance | Suited for minimalist designs |

| 1.5' x 3' | Medium size for balance | Versatile for various applications |

| 4' x 4' | Large size for prominence | Ideal for bold statements |

Custom dimensions offer the possibility of a truly unique design, tailored to specific needs. However, the choice of shape and size is only the beginning. Material options, being the next point of focus, influence the durability, appearance, and cost of the nameplate, thus requiring careful consideration.

Exploring material options plays a key role in the process of customizing aluminum nameplates.

Anodized aluminum, known for its durability and resistance to corrosion, serves as a popular choice.

Another variant, anodized debossable aluminum, allows for the creation of permanent, legible markings while offering the freedom to select an appropriate thickness, thereby ensuring an optimal balance between robustness and flexibility.

Anodized aluminum offers a robust and corrosion-resistant solution for custom nameplates, enhancing both their longevity and aesthetic appeal. The process of anodizing enhances the natural toughness of aluminum, providing benefits such as increased resistance to wear and tear, and protection against environmental elements.

Furthermore, anodized aluminum nameplates offer a wide range of color options, enabling customization to match any aesthetic preferences. In terms of maintenance, these nameplates require minimal upkeep due to their durability. While the process of anodizing does have an environmental impact, it is less significant than that of other metal treatments, making it a relatively eco-friendly choice.

Delving into durability factors, the anodized layer contributes to the longevity of the nameplate. The discussion will be broadened in the subsequent section to consider the specific advantages of anodized debossable aluminum.

Debossable varieties of this robust material exhibit additional advantages, particularly with regards to their physical durability and aesthetic versatility. The anodizing benefits include enhanced resistance to wear and tear, providing a long-lasting finish. The color options are diverse, giving users control over the aesthetic outcome.

| Durability Factors | Maintenance Tips |

|---|---|

| Resistant to corrosion and UV radiation | Regular cleaning with mild detergent |

| Retains color and gloss over time | Avoid abrasive materials that can scratch the surface |

| Withstands high temperatures | Periodic inspection for damage |

The environmental impact of anodized debossable aluminum is minimal as the anodizing process doesn't produce hazardous waste. This material is also recyclable, reducing its ecological footprint. Transitioning into the next topic, one must consider the thickness of the aluminum when designing a custom nameplate.

Selecting the appropriate thickness for your material is a critical consideration that can significantly influence the durability and functionality of the final product. Aluminum durability is closely tied to its thickness, with thicker plates offering greater resistance to environmental stressors.

Moreover, thicker plates may offer cost efficiency in terms of longevity, reducing the need for frequent replacements. However, installation methods must be considered as thicker plates may require more complex anchoring systems.

Maintenance tips may also vary depending on the thickness chosen. For instance, thicker plates might need specific types of cleaning agents to preserve their finish.

Furthermore, the thickness of the aluminum can have an environmental impact, especially if thicker plates are left unused. Thus, understanding the implications of aluminum thickness is crucial before exploring material and finish options.

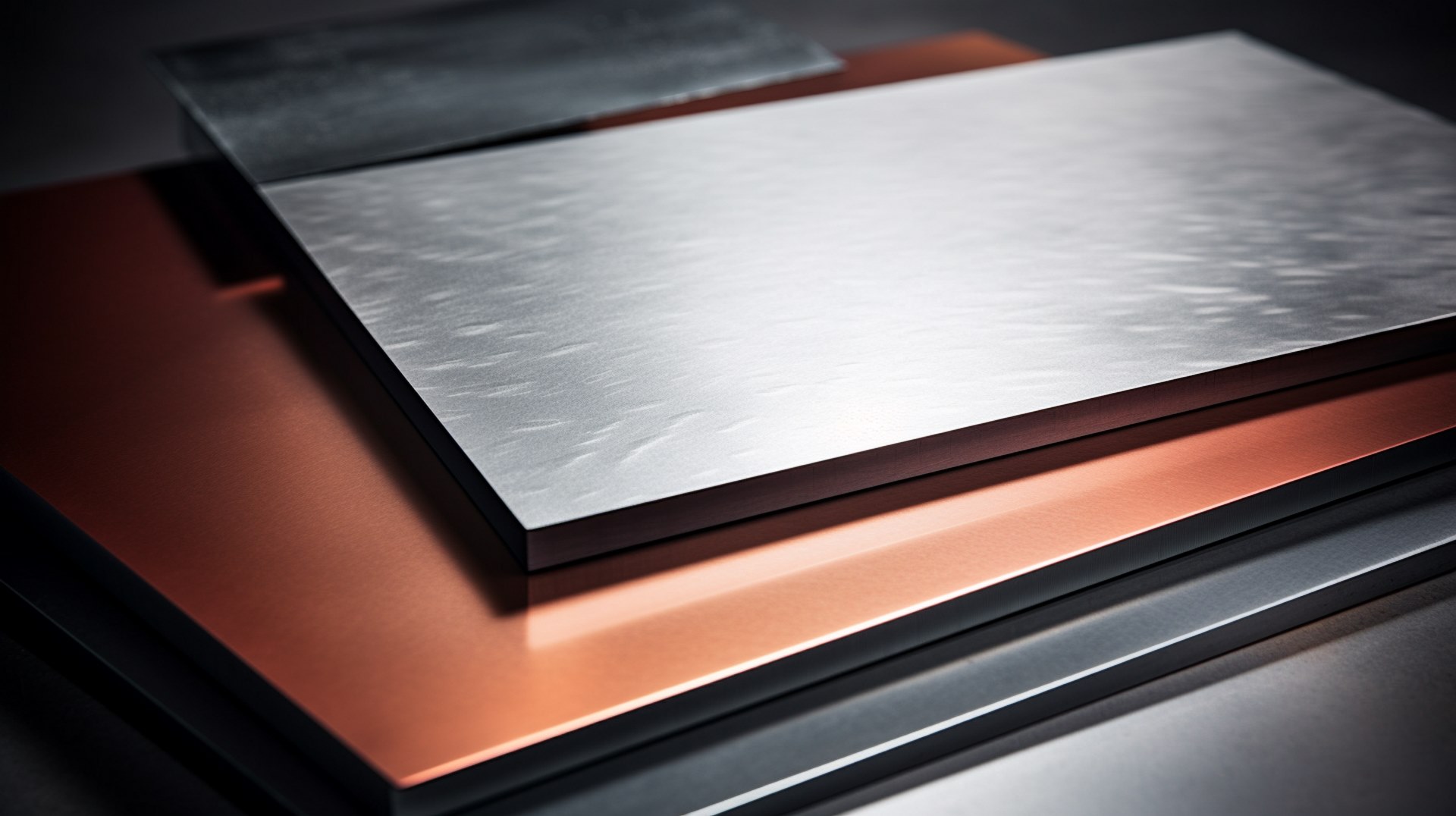

Exploring the realm of material and finish options for custom nameplates entails an understanding of the unique properties and advantages of several key materials.

Aluminum, anodized aluminum, brass, and stainless steel each offer distinct benefits and aesthetic qualities.

The subsequent discussion will delve into these materials, dissecting their respective traits and the implications of their use in nameplate production.

In the realm of nameplates, aluminum stands as a mighty fortress, offering durability, versatility, and a sleek aesthetic appeal that satisfies a wide range of design requirements. Renowned for its corrosion resistance, aluminum withstands harsh elements, providing longevity and effectiveness to nameplates. This robustness is further enhanced by the selection of suitable alloy types, customized to meet specific design criteria.

A significant aspect of aluminum sourcing is the environmental impact. Aluminum recycling, a widely implemented practice, significantly reduces the carbon footprint, thus offering an eco-friendly option. This practice affirms control over environmental consequences while maintaining product quality.

The versatility of aluminum extends beyond its initial state, leading to numerous finishing options. One such option, which will be discussed in the following section, is anodized aluminum.

Anodization, a transformative process, significantly enhances the inherent strength and corrosion-resistant properties of this popular metal, offering a myriad of aesthetic possibilities.

Beyond these anodizing benefits, durability comparison reveals that anodized aluminum outperforms unprocessed counterparts, withstanding harsh weather conditions, physical strain, and prolonged use.

In terms of color possibilities, anodization provides a wide spectrum, from vibrant hues to refined metallic tones, allowing for personalized aesthetics.

An additional benefit lies in the process's minimal environmental impact, as it produces no hazardous waste and uses less energy than other finishing methods.

Maintenance tips for this remarkable material include regular cleaning with mild, non-abrasive solutions to preserve its radiant finish.

As the exploration of metals for nameplates continues, the focus shifts towards another significant contender, brass.

Transitioning from the resilient and versatile nature of anodized aluminum, attention is now drawn to the inherent charm and elegance of brass. Noted for its aesthetic appeal, brass has been a preferred choice for nameplates for centuries.

Despite the numerous benefits associated with brass, one must consider its susceptibility to tarnish over time. The subsequent section will explore the characteristics of stainless steel, a material known for its exceptional resistance to tarnishing and corrosion.

Highly regarded for its exceptional resistance to tarnishing and corrosion, stainless steel represents a robust and durable material choice for nameplates. The stainless durability and steel aesthetics harmoniously blend to provide a finish that is not only visually appealing but also enduring.

| Attributes | Details |

|---|---|

| Corrosion Resistance | Stainless steel is inherently resistant to rust, staining, and corrosion, making it a perfect choice for outdoor and industrial applications. |

| Maintenance Tips | This material requires minimal maintenance, with occasional cleaning to retain its luster. |

| Recycling Stainless | Stainless steel is completely recyclable, thus contributing to environmental sustainability. |

As one navigates through these material options, it is important to consider the overall design and aesthetics. Moving forward, an exploration of various layout options for custom aluminum nameplates can further optimize their functionality and visual appeal.

Exploring various layout options, such as landscape or portrait position, and different engraving styles can significantly influence the overall aesthetic and functionality of a custom aluminum nameplate.

The choice between a landscape or portrait position plays a pivotal role in enhancing layout aesthetics and design versatility. Landscape layout may privilege wider, horizontal emphasis, suitable for elongated texts or designs. Contrastingly, portrait position offers a vertical emphasis, ideal for compact or stacked information arrangements.

Engraving styles contribute to the uniqueness of the nameplate, offering a range of aesthetic and practical benefits. Deep engraving, for instance, ensures layout longevity as it can withstand harsh environmental conditions without fading or wearing out. Moreover, choosing appropriate colors forms a crucial aspect of the design process. Color considerations include the contrast between the nameplate and the text, impacting visibility and legibility.

The placement of text is another critical factor to consider. Text placement must ensure the information is readable and aesthetically pleasing, balancing the elements of the nameplate.

The layout of a nameplate, therefore, requires careful consideration of several factors. Building on these considerations allows for the creation of a nameplate that is not only visually appealing but also durable and functional. Moving forward, it is equally essential to consider the options available for the corners of the nameplate.

After exploring the various layout options for custom aluminum nameplates, it is crucial to consider the corner options, which significantly influence the overall aesthetic and safety of the product.

There are different corner types to choose from, each with unique characteristics that can significantly impact the nameplate's overall look and functionality.

For example, rounded corners might be more suitable for high-traffic areas where interaction with the nameplate is frequent, while square corners could be preferable for locations with minimal contact. The corner style can also influence the installation methods used, as some may require specific equipment or techniques.

Selecting the appropriate corner option is a vital part of the custom nameplate design process. The following section will delve into the essential aspect of defining your custom specifications, ensuring a product that aligns seamlessly with your needs and expectations.

Delving into the realm of custom specifications for aluminum nameplates establishes a foundation for a thorough comprehension of the process.

It is imperative to consider factors such as the desired quantity, the precise dimensions of the nameplates, and the options for hole placement and diameter.

These variables significantly influence the final product and therefore demand careful deliberation and informed decision-making.

When considering custom aluminum nameplates, it becomes critical to determine the precise quantity needed, a decision that carries with it a sense of both intrigue and suspense. Bulk orders often come with significant cost factors and a longer production timeline, necessitating careful planning and design approval before order placements.

| Quantity | Cost Factors | Production Timeline |

|---|---|---|

| Small | Low | Short |

| Medium | Moderate | Moderate |

| Large | High | Long |

Given these parameters, choosing the right quantity helps balance needs and resources, ensuring that the customized aluminum nameplates are not only visually appealing but also economically viable. The strategic decision-making process, therefore, plays an integral role in the overall success of the project. The exploration of this topic further delves into the intricacies of choosing the right dimensions for these nameplates.

Determining the correct dimensions, including tag/plate width and height, is an essential step in the production of personalized identification plates, affecting both the aesthetic appeal and functionality of the final product.

Multiple factors influence the choice of size, such as:

Measurement accuracy is vital in this phase, avoiding potential inconveniences linked to dimensional aesthetics or fitting issues. Precision in the dimension selection process enables the creation of a custom aluminum nameplate that meets the user's requirements and expectations.

Further considerations include the positioning and size of holes, examined in the following section.

In the labyrinth of identification plate production, the choice of hole options emerges as a critical factor influencing both the usability and cost of the final product.

The presence or absence of holes in a custom aluminum nameplate not only drives the mounting techniques but also significantly impacts the durability assessment of the item.

Zero holes might seem cost-effective, but one or two holes, priced at $0.30 and $0.40 respectively, can enhance the installation methods and the overall design influence.

The option of four holes, though priced at $0.50, offers an elevated level of sturdiness.

Decisions regarding hole placement need to be made strategically, considering both the aesthetic and practical aspects of nameplate utilization.

This deliberation leads naturally to the next consideration: determining the appropriate diameter for these holes.

Choosing the correct hole diameter for identification plates is a crucial step that influences not just the fit and mount stability, but also the overall visual appeal of the final product. The hole diameter is determined by considering several factors, which include hole placement, countersinking holes, hole reinforcements, hole spacing, and tolerance requirements.

To ensure the successful implementation of these aspects, a deep dive into nameplate fabrication processes is warranted.

The fabrication process of nameplates involves a variety of techniques that result in unique and custom designs.

Among these techniques are embossing, a method that creates a three-dimensional effect on the nameplate.

Machining is a process that involves cutting and shaping the material into the desired form.

Metal etching is a procedure that uses chemicals to create detailed patterns and designs.

Each of these methods contributes to the final product's aesthetic appeal and functionality, making them crucial components of the nameplate fabrication process.

Elevating the aesthetic appeal of custom aluminum nameplates, embossing provides a tactile and visually captivating enhancement that makes the design stand out. The embossing process uses heat and pressure to create a raised or sunken design, offering a range of embossing techniques that can be tailored to meet the needs of diverse specifications.

The process of embossing sets the stage for further enhancements in the production of custom aluminum nameplates, such as the application of machining techniques.

Incorporating machining techniques into the production process further enhances the precision and aesthetic appeal of embossed items. Precision Machining, a crucial facet of this process, ensures meticulous detailing and exactness in dimensions, thus offering a higher degree of control to the users. It involves the use of CNC programming, a system that automates the operational parameters of the machine tools.

The accuracy of the machining process is further guaranteed by consistent machine calibration, a process that checks and corrects the machine's accuracy to ensure its performance meets the set standards. Regular tool maintenance is also essential to enhance the machine's operational longevity and maintain its precision.

The application of these machining techniques is a testament to the sophistication involved in the creation of custom aluminum nameplates. The next stage in this process involves the intricate method of metal etching.

Transitioning from the machining process, the production of custom aluminum nameplates often involves a crucial phase known as metal etching.

Despite its numerous benefits, it is imperative to follow safety precautions during the etching process owing to the involvement of corrosive chemicals.

In the realm of customization, metal etching stands as an effective method for tailoring aluminum nameplates. However, there are additional customization options that offer further possibilities for personalization, which will be discussed in the subsequent section.

Delving deeper into the realm of customization, one finds a plethora of options to personalize an aluminum nameplate, a veritable canvas for creative expression. The range of choices can be categorized under five key aspects: color variations, texturing methods, engraving techniques, logo incorporation, and protective coatings. These factors provide control and influence over the final product, enabling it to reflect the desired aesthetic and functional attributes.

| Color Variations | Protective Coatings |

|---|---|

| Offer a spectrum of hues that can be anodized or painted onto the aluminum surface. | Enhance the durability of the nameplate, safeguarding it from environmental elements. |

| Texturing Methods | Logo Incorporation |

|---|---|

| Enable different surface finishes, from mirror-like smoothness to rough, matte textures. | Allow for the integration of company logos or symbols, enhancing brand visibility and recognition. |

| Engraving Techniques |

|---|

| Provide the ability to carve intricate designs, patterns, or text onto the aluminum surface. |

The potential for customization allows for the creation of aluminum nameplates that are not only functional but also a reflection of the brand's identity. The ability to control color, texture, engraving, logo incorporation, and coating provides an expansive platform for personalization. Without summarizing, it is evident that these additional customization options offer a robust framework for creating distinctive, durable, and visually pleasing aluminum nameplates.

Pricing for custom aluminum nameplates is influenced by material selection, design options, engraving techniques, nameplate durability and environmental impact. Costs vary based on the complexity and sustainability of chosen materials and design.

Production speed for custom aluminum nameplates typically varies; however, including potential production delays, delivery methods may extend the process. Expedited options exist, and tracking shipments ensures control over the process timeline.

Maintenance for nameplates involves specific cleaning techniques, application of protective coatings, and damage prevention measures. Understanding weather impact is crucial, while adopting longevity tips can enhance durability and aesthetic appeal.

"Embarking on the journey of personalization, the availability of single custom aluminum nameplate orders depends on the supplier. Material quality, design options, and personalization methods influence minimum order quantities, assuring longevity and minimal environmental impact."

Installation methods vary based on material selection and nameplate durability. The personalizing process may present installation challenges. While installation services are not typically provided, comprehensive instructions are available to ensure successful application.

In conclusion, the art of creating custom aluminum nameplates is akin to sculpting a masterpiece; it involves a complex interplay of design considerations, material selection, and fabrication processes.

With an array of shapes, sizes, and finishes available, the versatility of aluminum makes it a sought-after choice for nameplates.

Every detail, from the corners to the layout, can be meticulously tailored to meet unique specifications, rendering each nameplate a distinctive identity marker.

Elevate your brand or project with our specialized metal and non-metal nameplates. Gold Hot Industrial Co., Ltd. pioneers bespoke designs, catering to various industries. Whether for furniture labels, advertising, crafts, or more, our precision stamping and casting machines ensure top-quality products.

Contact us for a free quote for customizing your ideal aluminum nameplate!