In the vast landscape of industrial identification and branding, the humble, yet powerful, custom metal nameplate holds a unique position. Renowned for its durability and versatility, this simple object serves as a silent ambassador for countless products, equipment, and machinery.

The process of its creation - from a simple concept to the final product - is indeed a fascinating journey that entails a blend of creative design, precise engineering, and meticulous fabrication. This discourse intends to shed light on this intriguing process, revealing the intricate steps and considerations involved.

As we journey through this exploration, you might find yourself surprised at the complex artistry and technical precision that underlies each custom metal nameplate you encounter.

In the realm of metal nameplates, a variety of types have emerged to serve specific purposes, including metal logo plates with contact information, machine tags, product identification plates, and more. These metal nameplate designs have been shaped by the distinct needs of various industries and applications.

Customization options abound, providing users the ability to dictate the look and feel of their nameplates. One could opt for static or variable data, or even include instructional tags. The choice of materials also plays a crucial role. Depending on the intended use, one might choose a material that is resistant to corrosion, extreme temperatures, or other environmental factors.

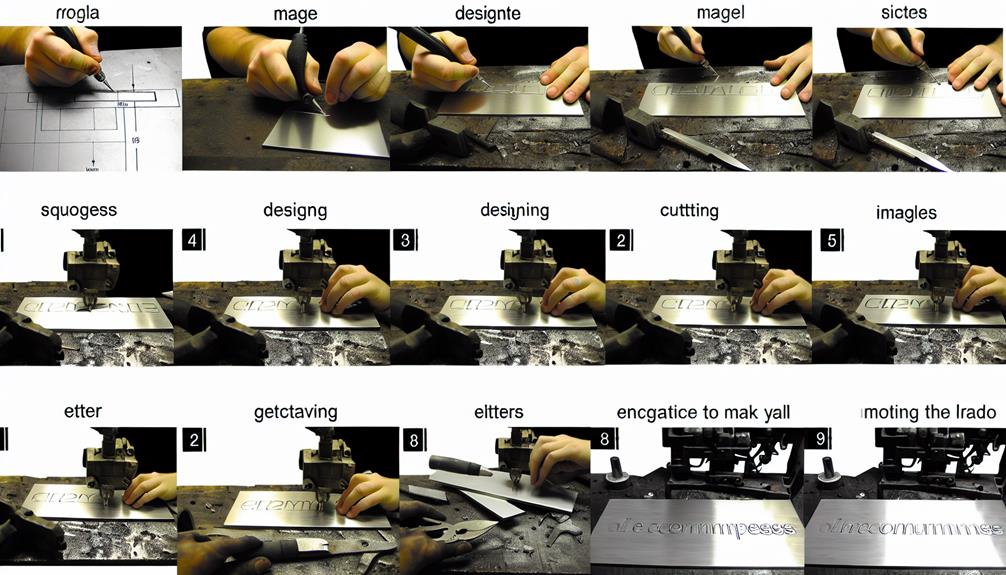

The production process for these nameplates is rigorous, ensuring quality and durability. It involves etching, engraving, or printing the design onto the chosen material, followed by cutting and shaping the plate to the desired dimensions. Design proofing is an essential step in this process, ensuring the final product is error-free and matches the customer's specifications.

Thus, the varied types of metal nameplates, with their vast customization options, diverse material choices, and meticulous production process, offer a high degree of control to the user, catering to their specific needs and preferences.

A Metal Equipment Nameplate, crafted from robust materials like screen printed aluminum or stainless steel, serves as an enduring identification tool for equipment, particularly in harsh environments. This metal identification process offers a durable solution for equipment branding and nameplate customization, ensuring the legibility of the information over the lifespan of the equipment.

Equipment branding through Metal Equipment Nameplates is a crucial aspect of industrial applications. These nameplates resist abrasion, chemicals, and direct sunlight, ensuring that your equipment maintains a professional and identifiable presence throughout its usage. The customization of these nameplates is an added benefit, allowing for the addition of logos or specific information, aiding in the tracking inventory process.

Uniquely, Metal Equipment Nameplates are not just for identification and branding. They also play a vital role in tracking inventory, particularly in industrial settings where large quantities of equipment are circulated. With custom metal nameplates, you gain control over your equipment management, ensuring that each piece of equipment is accurately and efficiently accounted for.

Custom Metal Nameplates offer a range of features, skillfully fabricated to meet precise specifications and suitable for a variety of demanding environments. These nameplates provide an array of customization options, allowing clients to take control of the design process from start to finish.

The design process begins with the selection of material choices. Depending on the intended application, clients can choose from a variety of materials that withstand high temperatures and caustic environments. This ensures that the nameplates remain durable and functional even under harsh conditions.

As part of the customization options, clients can choose to have etched or stamped serial numbers that provide static or variable data. This flexibility allows for a high degree of personalization to meet specific requirements.

Adhesive options are also available, with the choice of using NFI Corp's engineered adhesives or precise screw holes for mechanical attachment. This provides the flexibility to cater to various mounting preferences.

Metal nameplates serve a multitude of functions in various industries. They are primarily used for identification, tracking, and inventory, providing instructions, ensuring safety, and enhancing branding efforts.

Each of these applications is essential, and its importance cannot be overstated in ensuring efficient business operations.

In numerous industries such as manufacturing, food service, and construction, the use of metal nameplates for identification purposes - denoting model names, part numbers, or other relevant information - can significantly enhance productivity and ensure quality outcomes. Material options can vary, including stainless steel or aluminum, based on design considerations and durability factors.

For example, in harsh outdoor environments, a corrosion-resistant metal may be best. The benefits of customization are manifold: distinct logos, unique fonts, and specific colors can be utilized to reinforce brand identity, optimize visibility, and improve inventory control.

Therefore, whether it's a heavy machinery producer needing clear, durable labels, or a restaurant chain seeking branded equipment tags, the flexibility and resilience of custom metal nameplates prove invaluable.

Beyond identification, metal nameplates serve a vital role in asset tracking and inventory management, particularly in sectors requiring durable and enduring labels. They offer a dependable solution for comprehensive logistical control, ensuring assets are identifiable and traceable.

These custom metal nameplates incorporate features that enhance their utility in maintaining asset control, such as:

Aside from their role in asset tracking and inventory management, metal nameplates are often utilized for instructional purposes, providing essential operational guidelines and identifying critical controls on various types of equipment. They offer installation tips, operation instructions, maintenance guide, troubleshooting steps, and even serve as a user manual in some instances.

For example, a metal nameplate on a copy machine might visually depict the appropriate steps to clear a paper jam. Similarly, nameplates on manufacturing equipment often highlight the critical operating buttons and levers, defining their functions. The aim is to make the control of these complex machines more intuitive and user-friendly. Hence, custom metal nameplates are not just for identification, but also for instruction, assisting in the efficient utilization of the equipment.

Remarkably, metal nameplates also significantly contribute to safety measures, serving as enduring reminders of potential hazards and necessary precautions in various settings.

The potency of these protective tools lies in their ability to effectively communicate critical information, ensuring:

These nameplates play a crucial role in enhancing workplace compliance and fostering a safety culture. They serve as constant, durable reminders, providing guidance for correct procedures, and alerting individuals to possible dangers. This combination of functionality and durability makes custom metal nameplates an invaluable tool in maintaining safety standards.

In the realm of branding, metal nameplates serve a significant role in enhancing product recognition and elevating brand perception. These nameplates are not just decorative elements but powerful marketing tools that contribute to effective branding strategies.

They are employed as marketing tactics to foster customer engagement and facilitate product differentiation in a highly competitive marketplace. When a product features a high-quality metal nameplate bearing the company's logo or name, it not only helps in establishing brand recognition but also conveys an image of quality and reliability.

This, in turn, instills a sense of trust and loyalty among consumers. Therefore, metal nameplates are an invaluable asset in the branding toolbox, offering companies a subtle yet impactful way to assert their brand identity and value.

The versatility of metal nameplates is clearly demonstrated through their extensive application in various industries, ranging from transportation and construction to manufacturing and property management. The durability benefits, customization options, versatile applications, and long-lasting investment of these nameplates have made them a preferred choice for businesses. Moreover, their creative design possibilities further add to their appeal.

Metal nameplates are commonly used in:

These varied applications underline how metal nameplates can be tailored to suit specific needs, demonstrating their versatility and adding value to the industries they serve.

Building on their varied applications, metal nameplates find extensive use across several industries, with special emphasis on foodservice and restaurants, automotive, marine and recreational vehicles, industrial, construction, and manufacturing, and aerospace.

Metal nameplate applications in healthcare are significant due to their durability and ease of cleaning, crucial in maintaining sterile environments. Furthermore, custom metal nameplates in hospitality, such as hotels and restaurants, add a touch of elegance and personalization, enhancing the customer experience.

In the automotive, marine, and aerospace sectors, metal nameplates are indispensable for branding, model identification, and safety information. They withstand external environmental conditions, affirming their longevity.

In the retail industry, the benefits of metal nameplates lie in their premium aesthetic appeal, boosting brand perception and driving customer engagement. Similarly, technology product companies utilize metal nameplates to highlight brand identity and ensure product authenticity.

The industrial, construction, and manufacturing sectors value metal nameplates for their durability and resistance to harsh conditions, aiding equipment identification and safety protocol adherence.

Despite their wide application, it is essential to consider the environmental impact of metal nameplate production. Manufacturers are now adopting greener practices to minimize waste and reduce carbon footprints, ensuring a sustainable future for this versatile product.

Delving into the manufacturing process of a custom metal nameplate, one finds a blend of intricate procedures and sophisticated technologies. The process begins with the selection of eco-friendly materials that ensure nameplate longevity. The material chosen undergoes rigorous durability testing to withstand harsh environments and maintain its aesthetic appeal.

The process involves:

This entire process respects the environment by incorporating recycling nameplates back into the production cycle. This ensures a minimal carbon footprint, aligning with the growing demand for sustainable operations.

The end product is not just a nameplate; it's a perfect blend of durability, design, and environmental responsibility. It's a testament to the sophistication of the manufacturing process and the potential for customizing to specific needs.

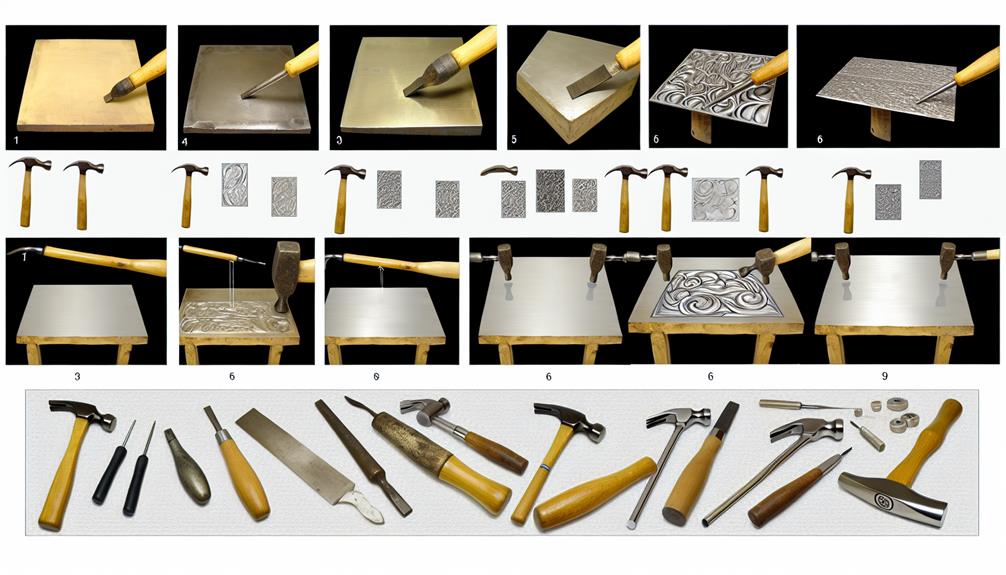

Having explored the general manufacturing process, let's now examine specific fabrication techniques such as embossing, machining, and metal etching that are critical in the creation of custom metal nameplates.

Embossing is a fabrication technique that enhances custom design by adding a three-dimensional aspect to the nameplate. The end product is a durable identifier that remains legible even after years of exposure to harsh environments. Material selection plays a significant role in this process, as the chosen material must be malleable enough to be shaped yet robust enough to withstand wear.

Machining, another crucial technique, involves using machine tools to cut raw materials into the desired shape and size. This process further enables the customization of the nameplate design, offering accuracy and precision.

Metal etching, typically used for products placed outdoors, is a highly durable process. It involves engraving the nameplate with acid, creating a lasting imprint resistant to harsh elements.

Durability testing forms a crucial part of these processes, ensuring the product can withstand the intended environmental conditions. After fabrication, finishing options such as anodizing, powder coating, or painting may be applied to enhance the product's aesthetic appeal and durability.

When creating a custom metal nameplate, there are several customization options available to suit your specific needs.

These options include:

Additionally, you can personalize the color of your nameplate for a truly unique design.

In the realm of custom metal nameplates, the possibilities for shapes and sizes are virtually limitless, allowing for a high degree of personalization in your design. This element of design versatility caters to your unique needs, with material durability and longevity factors being prioritized.

Our custom solutions consider:

Your desired shape and size, coupled with these considerations, enable you to design a custom metal nameplate that truly represents your brand's identity and withstands the test of time.

The height of your custom metal nameplate is a critical dimension, offering further opportunities for customization and brand distinction. The right height enhances the visual impact and readability of your nameplate while ensuring durability and accommodating installation considerations.

The table below provides an overview of how plate thickness, height durability, visual impact, height readability, and installation considerations interplay in the customization process:

| Factors | Importance | Considerations |

|---|---|---|

| Plate thickness | Directly affects the durability and height of the nameplate | Thicker plates offer more durability but may affect the height |

| Height Durability | Determines the longevity of the nameplate | Higher plates may be more susceptible to damage |

| Visual Impact | Plays a key role in brand recognition | Greater height can increase visibility |

| Height Readability | Ensures the information on the nameplate is legible | Height should be balanced with font size |

| Installation Considerations | Affects the placement and security of the nameplate | The height should align with the installation surface |

In essence, the height of your metal nameplate should reflect your brand's image while meeting practical needs.

Just as the height, the width of your custom metal nameplate plays a significant role in the overall design, with a myriad of customization options available to suit your branding and practical needs.

Choosing the right material and finish for your custom metal nameplate is a critical step. Options include Aluminum, Anodized Aluminum, Metalphoto, Brass, and Stainless Steel. Each material selection offers unique customization possibilities regarding surface finishes, promoting durability and longevity of your nameplate.

To provide design flexibility, a variety of color options are available, ranging from metallic hues to vibrant shades. Custom sizing and adhesive options further allow for a tailored fit to your specific requirements. Furthermore, font choices and logo placement can be adjusted to your liking, ensuring the nameplate aligns with your brand identity.

Therefore, considering these elements in your custom metal nameplate design will result in a product that not only meets your functional needs but also complements your aesthetic preferences.

In the realm of custom metal nameplate design, color choice plays a pivotal role, offering a broad spectrum of possibilities to match your brand's visual identity. The color selection process is not merely an aesthetic concern but also an exploration of color psychology, intended to evoke specific emotions or reactions.

Ultimately, the right color choice is a vital aspect of creating a powerful, enduring visual impact.

Beyond aesthetic elements, the adhesive used in metal nameplates is another crucial customization factor, contributing significantly to the product's functionality and durability. The adhesive longevity, temperature effects, adhesive removal, surface preparation, and adhesive strength are key considerations.

| Factor | Importance | Considerations |

|---|---|---|

| Adhesive Longevity | Determines the lifespan of the nameplate | Choose an adhesive based on the expected lifespan of the nameplate |

| Temperature Effects | Adhesive performance can vary with temperature | Consider the environment where the nameplate will be used |

| Adhesive Removal | Ease of removal may be necessary | Select an adhesive that allows for easy removal if needed |

| Surface Preparation | Proper surface prep enhances adhesive strength | Ensure the surface is clean and dry for optimal adhesion |

While considering various aspects of customizing your metal nameplate, the selection of an appropriate font plays a pivotal role in enhancing its aesthetics and legibility. A well-chosen font can make your nameplate stand out and communicate your message clearly and effectively.

In essence, font selection can significantly influence the overall impression and effectiveness of your custom metal nameplate.

Adjusting the text lines on your custom metal nameplate offers additional opportunities for personalization, enhancing both its functionality and aesthetic appeal. Your design inspiration can play a significant role in dictating the line structure, impacting the overall presentation of the nameplate.

When considering line adjustments, material selection is crucial. Certain materials offer better flexibility and durability factors for intricate line designs. This can influence cost analysis, as more complex designs may require a higher investment.

Furthermore, different line structures may require specific installation techniques to ensure optimal visibility and longevity. For instance, deeply etched lines might need certain mounting solutions to avoid wear and tear.

After finalizing the line structure, the next pivotal aspect of creating custom metal nameplates is determining the logo position, a critical element that can significantly influence the overall design and aesthetic appeal. The positioning of the logo can either magnify or reduce its relevance and visibility. This strategic placement can also impact the logo's aesthetics, durability, and color contrast.

Carefully consider the following when deciding on the logo position:

The customization of metal nameplates involves a series of processes to ensure they meet specific requirements and standards.

It begins with proofing, moves on to determining the size, and includes list submission, all before the application of potential set-up fees.

We will now explore these points to gain a comprehensive understanding of the customization processes involved in creating metal nameplates.

In the intricate process of customizing metal nameplates, proofing emerges as a critical step to ensure the accuracy and quality of the final product. This phase involves several key elements that contribute to the overall success of the nameplate, including:

This meticulous proofing process validates the nameplate's value, providing you with confidence and control over the final product.

How significant is the role of size in the customization process of metal nameplates?

Size is crucial as it has direct implications on the durability factor, installation methods, weather resistance, maintenance, and cost analysis.

Large metal nameplates may offer enhanced visibility and durability, but they also require more resources and complex installation methods, affecting the cost.

Conversely, small nameplates are less resource-intensive, easier to install, and more cost-effective. However, they might not withstand harsh weather conditions as effectively.

Maintenance tips vary depending on the size as well; larger plates may require more frequent servicing.

Thus, size is a critical variable to consider in the customization processes, offering a balance between visibility, durability, cost-effectiveness, and ease of maintenance.

While considering the customization of metal nameplates, the submission of design preferences plays a pivotal role in achieving the desired outcome. This process enables the production of nameplates that not only reflect the client's vision but also align with current nameplate trends.

In the list submission process, consider the following:

After considering the design aspects, one must also understand the intricate process involved in the customization of metal nameplates. It typically starts with design inspiration, which sets the tone for material selection. The choices made here greatly influence the nameplate's durability. A more robust material ensures longer life, while a delicate one might require more careful handling.

Maintenance tips come into play next, ensuring that the nameplate withstands the test of time. Regular cleaning, avoiding harsh chemicals, and observing any changes in texture or colour can help in maintaining the nameplate's original look.

Lastly, installation methods vary based on the chosen design and material. It's crucial to follow the recommended practices to avoid any potential damage.

In the customization process of metal nameplates, one cannot overlook the significance of set-up fees, which form an integral part of the overall expenditure. These fees can occasionally harbor hidden costs, requiring careful attention to pricing negotiations.

To provide customers with a sense of control, it's essential to consider:

It's imperative to understand these aspects to ensure a cost-effective production process.

The production stage of custom metal nameplates involves a series of intricate processes designed to deliver a product that meets the specific needs and preferences of the client. Initially, proper metal sourcing is conducted to ensure the material's suitability for the desired design.

The production timeline is strictly followed to ensure timely delivery without compromising the product's quality. Quality control is a priority during production, with rigorous checks in place to prevent errors. Production costs are meticulously managed to provide the client with a high-quality product at an affordable price.

Lastly, post-production treatments are done, such as coating or engraving, to enhance the nameplate's durability and aesthetic appeal. This process ensures a superior, personalized product.

Having meticulously crafted, inspected, and perfected the custom metal nameplates, the next crucial stage in the customization process is their prompt and secure shipping to the client.

At this stage, several key aspects are considered to ensure that the client receives their order in perfect condition and within the agreed timeframe. These include:

Efficiency and precision guide our reorder process, ensuring that repeat orders for custom metal nameplates are handled with the same meticulous attention to detail as the initial order. Our reorder logistics are designed to afford you control, from price considerations to supplier communication.

We maintain open channels of communication with our suppliers, ensuring that your requirements are clearly understood and executed. Quality assurance is integral to this process, with rigorous checks in place to guarantee the consistency of every nameplate produced.

Price considerations factor into our lead times, balancing cost-effectiveness with timely delivery. We value your time and investment, ensuring that our processes are streamlined, and reorders are managed with the utmost professionalism and dedication to quality.

The average lifespan of a custom metal nameplate depends on material selection, nameplate durability, environmental impact, aesthetic choices, and personalization options. Properly maintained, they can last for decades, even in harsh conditions.

To ensure longevity of your custom metal nameplate, utilize appropriate cleaning techniques, apply protective coatings, consider environmental factors, focus on damage prevention, and periodically undertake nameplate restoration to maintain its appearance and structural integrity.

Yes, you can order a single custom metal nameplate. Design options, material choices, pricing factors, nameplate customization, and personalized engraving all contribute to the flexibility of our services, ensuring your individual needs are met.

The turnaround time for creating and delivering a custom metal nameplate depends on several factors including design options, material selection, engraving process, pricing factors, and the chosen delivery method. Expect an average of 2-4 weeks.

Yes, there are eco-friendly options for metal nameplates. Sustainable materials and green manufacturing practices can be used. Options include recycling metal nameplates and using biodegradable alternatives to lessen environmental impact.

In conclusion, custom metal nameplates manifest a multitude of applications in various industries.

Their unique features, flexible customization options, and meticulous manufacturing processes make them an indispensable tool for identification and branding.

From their conception to their creation, metal nameplates offer a durable, efficient, and aesthetic solution for many businesses, proving their paramount importance in the world of product marking and labeling.

Elevate your brand or project with our specialized metal and non-metal nameplates. Gold Hot Industrial Co., Ltd. pioneers bespoke designs, catering to various industries. Whether for furniture labels, advertising, crafts, or more, our precision stamping and casting machines ensure top-quality products.