Enamel pins have skyrocketed in popularity over the past few years, becoming a must-have accessory for many individuals and businesses.

However, one question that remains elusive is the cost associated with bringing these small pieces of art to life.

From the initial design and conceptualization to the materials selected, manufacturing process, customization options, and packaging, there are multiple factors that contribute to the overall cost of enamel pins.

In this discussion, we will explore each of these elements in detail, providing you with a comprehensive understanding of the expenses involved in creating these coveted collectibles.

So, hang tight as we uncover the intriguing world of enamel pin production and unravel the monetary mysteries behind their creation.

Design and conceptualization play a crucial role in the development of enamel pins, as they determine the overall aesthetic appeal and message conveyed by these small but impactful accessories. Keeping up with design trends is essential to creating enamel pins that resonate with the target audience. Market research helps identify the preferences and interests of consumers, allowing designers to create pins that align with their desires.

To stay ahead of the competition, enamel pin designers must be aware of the latest design trends. This involves staying up-to-date with fashion, pop culture, and art movements. By incorporating elements that are currently popular or trending, designers can ensure their enamel pins will appeal to a wider audience.

Market research is a vital step in the design process. It involves analyzing the target market, understanding their preferences, and identifying any gaps in the market. This information helps designers create enamel pins that fulfill the needs and desires of consumers. By conducting thorough market research, designers can make informed decisions about the design elements, colors, and themes of their enamel pins.

Design and conceptualization are the foundation of successful enamel pin production. By staying current with design trends and conducting thorough market research, designers can create enamel pins that not only look visually appealing but also resonate with the target audience.

Material selection is a critical aspect of enamel pin production, as it determines the durability, quality, and overall aesthetic of the final product. When considering the cost factors and production methods involved, it is essential to choose materials that not only meet the desired design requirements but also fit within the allocated budget.

The choice of material for enamel pins can vary depending on factors such as the intended purpose, design complexity, and budget constraints. Common materials used include brass, iron, copper, and zinc alloy. Each material has its own unique characteristics that affect the pin's appearance, weight, and durability.

Cost factors play a significant role in material selection. While brass and copper are often preferred for their durability and high-quality finish, they can be more expensive compared to iron or zinc alloy. However, opting for cheaper materials may compromise the overall quality and longevity of the enamel pin.

Production methods also influence material selection. For example, if the design requires intricate details or fine lines, a softer metal like brass or copper would be more suitable for the etching process. On the other hand, iron or zinc alloy may be more appropriate for designs that require a textured or embossed look.

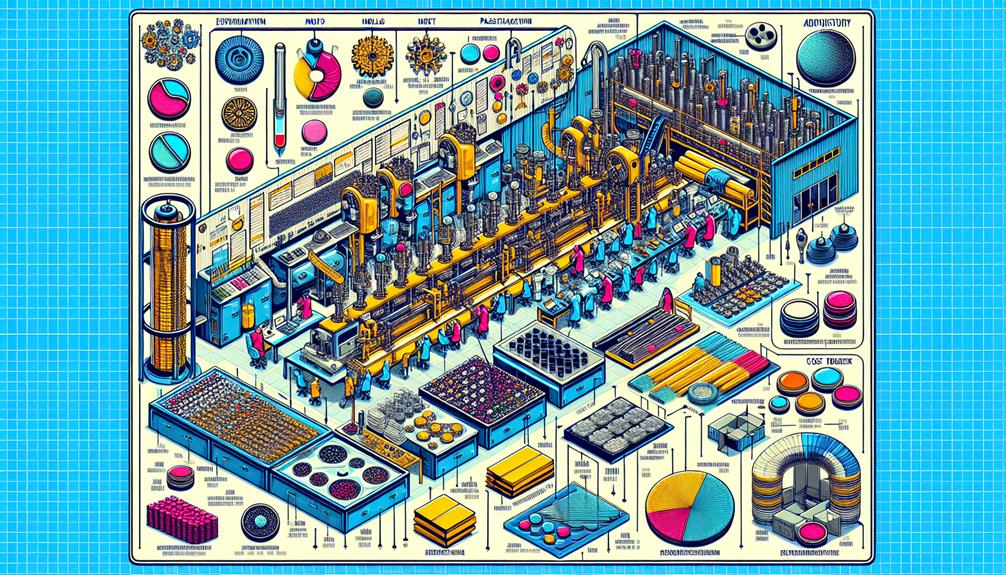

The manufacturing process of enamel pins involves several key points that need to be considered.

These include the cost breakdown, material selection, and production timeline.

Understanding these points is crucial in ensuring a smooth and efficient production process.

The production stage of enamel pin manufacturing entails a comprehensive breakdown of costs involved in the manufacturing process.

The first cost factor to consider is the design process. This includes the creation and refinement of the pin design, as well as any necessary adjustments to ensure its production feasibility.

Other cost factors include the materials used, such as the base metal and enamel, as well as any additional elements like glitter or rhinestones.

The manufacturing process itself involves several steps, including mold creation, metal plating, enamel filling, and polishing. Each of these steps contributes to the overall cost.

Finally, packaging and shipping costs should also be taken into account.

During the manufacturing process of enamel pins, careful consideration must be given to the selection of materials used. Material sourcing plays a crucial role in determining the overall quality, durability, and cost of the final product.

When it comes to enamel pins, there are various pricing factors that need to be taken into account when selecting materials. The type of metal used for the pin base, such as iron or brass, can significantly impact the cost. Similarly, the quality and thickness of the enamel coating, as well as the type of backing, can also affect pricing.

To maintain control over costs, manufacturers must carefully evaluate material options and negotiate with suppliers to ensure the best combination of quality and affordability.

The production timeline for enamel pins involves a series of carefully coordinated steps. From design to delivery, each stage is crucial in ensuring the final product meets the desired specifications.

The timeline begins with the creation of a digital or hand-drawn design, which is then converted into a mold. Once the mold is ready, the production process begins, starting with the injection of molten metal into the mold to form the pin base.

Next, the pins are plated, polished, and filled with enamel colors. After curing, the pins undergo quality control checks to ensure they meet the required standards. Finally, the pins are packaged and prepared for shipment.

It's important to note that the production timeline can vary depending on factors such as complexity of design, order quantity, and production costs.

A wide range of customizable options are available for enamel pins, allowing individuals to create unique and personalized designs. Whether you are creating custom pins for promotional purposes, as a fashion statement, or to commemorate a special event, the customization options are virtually limitless.

Here are some of the customization options to consider when designing enamel pins:

When it comes to packaging and presentation of enamel pins, there are two important points to consider: design and materials, and branding and customization.

The design and materials used for packaging should align with the overall aesthetic of the pins, while also providing protection during shipping and storage.

Additionally, branding and customization opportunities can be seized through personalized packaging, such as including the company's logo or adding special touches that enhance the unboxing experience for customers.

Design and materials play a crucial role in the packaging and presentation of enamel pins. The design process involves creating a visually appealing and unique pin design that captures the attention of the target audience. Production methods, on the other hand, determine the quality and durability of the enamel pin.

When it comes to packaging and presentation, the following factors should be considered:

To ensure a distinctive and memorable presentation, careful attention should be given to branding and customization when packaging enamel pins. Branding plays a crucial role in creating a strong identity for the product, while customization allows for a unique and personalized touch. One of the key elements of branding is logo design, which serves as a visual representation of the brand identity. The logo should be strategically placed on the packaging to create a lasting impression. Additionally, customization options such as custom packaging materials, colors, and finishes can further enhance the brand image and make the pins stand out from the competition. A well-designed and customized packaging not only adds value to the product but also leaves a lasting impression on the customers.

| Customization Options | Description | Benefits |

|---|---|---|

| Custom packaging materials | Using unique materials such as velvet or embossed paper | Enhances the perceived value of the product |

| Colors and finishes | Choosing specific colors and finishes for the packaging | Reinforces brand identity and creates a cohesive look |

| Personalized messages or notes | Including handwritten notes or personalized messages | Adds a personal touch and enhances customer experience |

In the realm of enamel pin production, there are various factors that contribute to additional costs and considerations. When calculating the total expenses of producing enamel pins, it is important to take into account the following factors:

Considering these additional expenses and production factors is essential to ensure control over the budget and to make informed decisions throughout the enamel pin production process.

When it comes to ordering enamel pins, there are often minimum quantity requirements. Additionally, if you desire a custom shape for your pins, it may further impact the minimum order quantity.

When creating enamel pins, you have the option to customize the shape of your design. However, it is important to consider any limitations in terms of complexity or size that may affect the manufacturing process.

There is a difference in cost between hard enamel and soft enamel pins due to variations in the enamel pin manufacturing process. Hard enamel pins have a higher production cost but offer a more durable and polished finish, while soft enamel pins are more cost-effective and provide a textured and dimensional look.

When it comes to rush production or expedited shipping of enamel pins, it is important to consider any additional fees that may apply. These fees can vary depending on the supplier and the urgency of the order. It is advisable to inquire about these fees beforehand to have better control over the costs.

In order to ensure satisfaction and quality, it is possible to request a sample of your enamel pin before placing a bulk order. This allows for a visual confirmation and the ability to make any necessary adjustments.

In conclusion, the cost of making enamel pins depends on various factors such as design complexity, material selection, customization options, packaging, and additional considerations.

Like a skilled artist carefully crafting a masterpiece, each step in the process contributes to the final product.

Just as a painter uses vibrant colors to bring a canvas to life, the selection and combination of materials play a vital role in creating unique and eye-catching enamel pins.

Elevate your brand or project with our specialized metal and non-metal nameplates. Gold Hot Industrial Co., Ltd. pioneers bespoke designs, catering to various industries. Whether for furniture labels, advertising, crafts, or more, our precision stamping and casting machines ensure top-quality products.

Contact us for a free quote for customizing your ideal Enamel Pins!