In the realm of visual identification, metal badges have persisted as an enduring symbol of authority, affiliation, or recognition. This article aims to present a comprehensive overview of custom metal badges, exploring their definition, potential applications, and the materials commonly employed in their fabrication.

Additionally, it will delve into the process of creating personalized badges and consider the factors that impact their cost. By providing an impartial examination of these topics, readers will gain a comprehensive understanding of custom metal badges and their significance in various contexts.

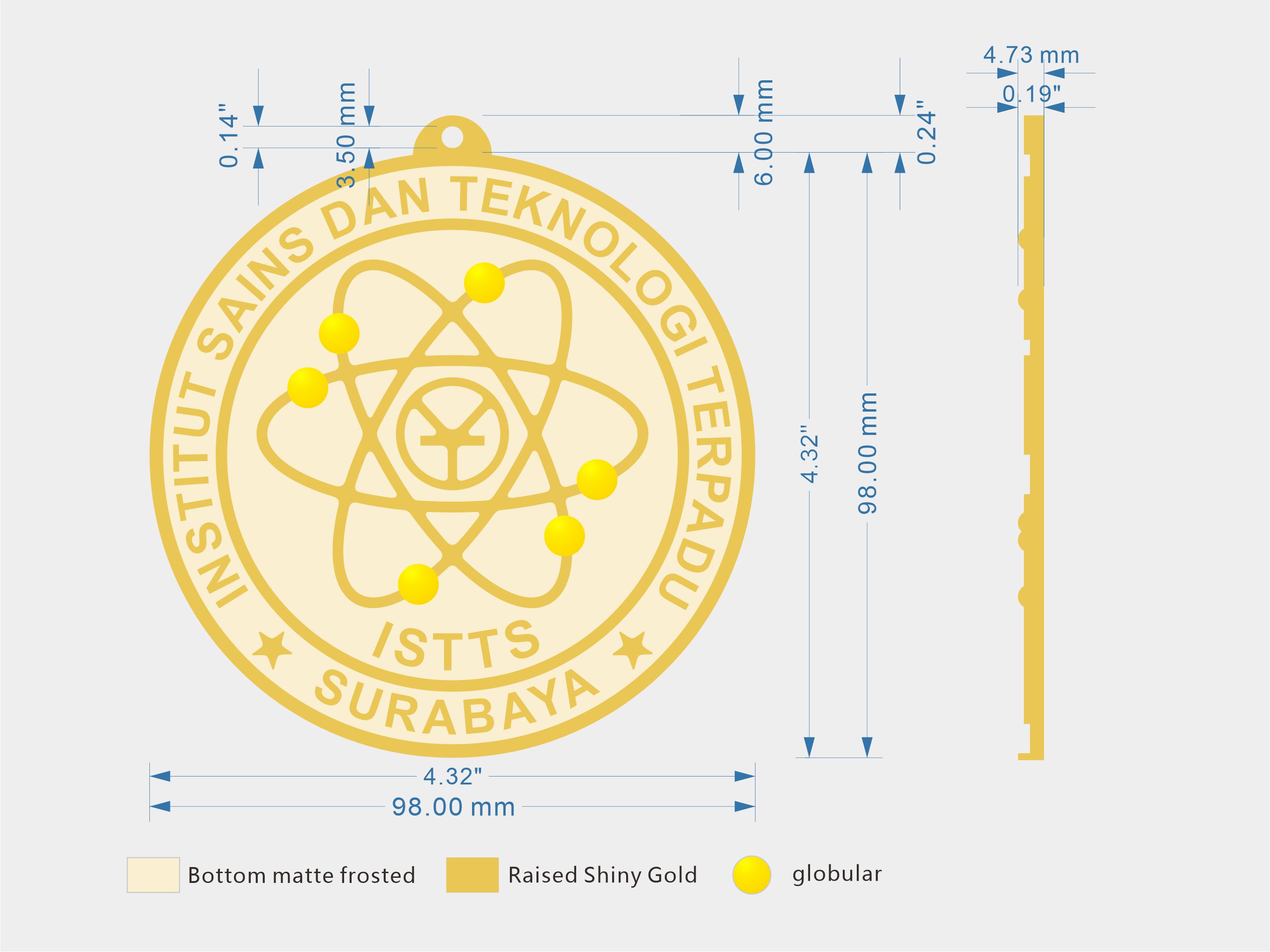

A metal badge is a small piece of metal that is typically worn or displayed to indicate membership, authority, or achievement. It is often designed with unique symbols, logos, or text to represent a specific organization, group, or individual accomplishment. Metal badges are commonly made from materials such as brass, zinc alloy, or stainless steel due to their durability and ability to withstand everyday wear and tear.

These badges serve multiple purposes in various contexts. For instance, in law enforcement agencies, metal badges are utilized as identification tools for police officers and other personnel. They signify the authority and legitimacy of those who wear them while performing their duties. Additionally, metal badges can be used by organizations such as schools or businesses to identify members of specific groups or teams. They act as visual representations of affiliation and help establish a sense of belonging.

Furthermore, metal badges can also be awarded as recognition for achievements in fields like sports, academics, or military service. These commemorative badges symbolize accomplishment and can be displayed proudly on uniforms or personal belongings.

Considering the versatility of metal badges in indicating affiliation and recognizing achievements across different domains, it becomes essential to explore the question: 'What can I use my metal badge for?'

One potential application for metal badges is to serve as identification markers or symbols of affiliation in various organizations or events. Metal badges can be used to establish authority, recognize achievements, or indicate membership. They are commonly worn by individuals in professions such as law enforcement, military personnel, and security guards to easily identify their position and responsibilities. In addition, metal badges can be utilized in conferences, seminars, and trade shows to identify participants based on their roles or areas of expertise. These badges not only provide a visual representation of the wearer's association but also facilitate networking opportunities among attendees.

Metal badges are also popularly used in schools and universities to mark students' achievements or positions within academic organizations. For example, honor societies often award metal badges to signify membership and academic excellence. Similarly, sports teams may use metal badges as awards for outstanding performance during competitions. Moreover, metal badges have found applications in community groups like scouting organizations or charity events where they can convey a sense of pride and belonging.

Understanding the materials that compose a badge is crucial for comprehending its durability and aesthetic appeal. So what specific type of metal is a badge made of?

The choice of material for a badge typically depends on factors such as durability, cost-effectiveness, and aesthetic appeal. When it comes to metal badges, various metals can be used based on these considerations. Commonly used metals for badges include brass, zinc alloy, stainless steel, and aluminum.

Brass is a popular choice due to its durability and classic appearance. It is resistant to corrosion and can withstand wear and tear over time. Zinc alloy is another commonly used material known for its affordability and versatility in design options. Stainless steel offers excellent durability and resistance to tarnish or rust, making it suitable for long-lasting badges. Aluminum is lightweight yet strong, making it an ideal option when weight or ease of attachment is a concern.

Each metal has its own unique properties that make it suitable for different badge applications. Factors like the intended usage environment, budget constraints, and desired aesthetics will influence the selection of the metal.

Knowing what materials are commonly used in badge production sets the stage for understanding how custom badges are made.

To create a personalized badge, the design is first conceptualized and then transferred onto a suitable material using techniques such as engraving, etching, or printing. The process begins with the creation of a digital or physical design. This design can be hand-drawn or created using graphic design software. Once the design is finalized, it is transferred onto the chosen material.

Engraving involves cutting the design into the surface of the material using specialized tools. Etching uses chemicals to remove layers of material and create a permanent image on its surface. Printing involves transferring the design onto the material using ink or other coloring agents.

After the design has been transferred onto the material, additional steps may be taken to enhance its durability and aesthetic appeal. These may include applying protective coatings or adding decorative elements such as enamel or gemstones.

With an understanding of how custom badges are made, one might wonder about their cost. The price of custom badges can vary depending on various factors such as size, complexity of design, choice of materials, manufacturing technique used, and quantity ordered.

In the next section, we will explore in detail how much custom badges typically cost and what factors can influence their pricing structure without explicitly mentioning 'step.'

The cost of personalized badges can be influenced by various factors, such as the size, complexity of design, choice of materials, manufacturing technique used, and quantity ordered. These factors play a crucial role in determining the overall cost of custom badges and can vary significantly from one project to another.

- Size: Larger badges may require more materials and time for production, resulting in higher costs.

- Complexity of design: Intricate designs with fine details or multiple colors may require advanced manufacturing techniques and additional labor, contributing to increased expenses.

- Choice of materials: The type of metal or other materials used for the badge affects its durability and aesthetic appeal. Premium materials like gold or silver are more expensive than standard options.

- Manufacturing technique: Different techniques such as die-casting or etching can be employed to create custom badges. Each method has varying levels of complexity and associated costs.

- Quantity ordered: Ordering a larger quantity often leads to economies of scale, reducing the unit cost per badge.

Understanding these factors is essential when considering the budget for custom badges. By analyzing each element's impact on cost, individuals or organizations can make informed decisions about their customization requirements while staying within their financial constraints.

In order to understand what factors affect the cost of a custom badge without explicitly stating 'step,' it is important to examine how each aspect contributes to pricing considerations.

Different factors contribute to the overall cost of a custom badge. Factors such as size, complexity of design, choice of materials, manufacturing technique used, and quantity ordered all play a role.

The size of the badge directly affects the amount of material needed for its production and therefore influences its cost. A larger badge will require more resources to manufacture and may also necessitate additional labor.

Similarly, badges with intricate designs are more time-consuming to produce and often require skilled artisans or advanced machinery, which can increase costs.

The choice of materials is another significant factor in determining the cost. Custom badges can be made from various metals such as brass, copper, or zinc alloy. Each metal has different properties and associated costs. For example, gold-plated or silver badges are generally more expensive due to the higher cost of these precious metals.

The manufacturing technique used also impacts the final price. Some methods like die-striking or casting are more complex and time-consuming than others like etching or printing. These techniques may require specialized equipment and skilled laborers who command higher wages.

Finally, the quantity ordered plays a role in determining the cost per unit. Manufacturers often offer discounts for bulk orders since they can optimize production processes and reduce overhead expenses.

Different factors contribute to the overall cost of a custom badge. Factors such as size, complexity of design, choice of materials, manufacturing technique used, and quantity ordered all play a role.

The size of the badge directly affects the amount of material needed for its production and therefore influences its cost. A larger badge will require more resources to manufacture and may also necessitate additional labor.

Similarly, badges with intricate designs are more time-consuming to produce and often require skilled artisans or advanced machinery, which can increase costs.

The choice of materials is another significant factor in determining the cost. Custom badges can be made from various metals such as brass, copper, or zinc alloy. Each metal has different properties and associated costs. For example, gold-plated or silver badges are generally more expensive due to the higher cost of these precious metals.

The manufacturing technique used also impacts the final price. Some methods like die-striking or casting are more complex and time-consuming than others like etching or printing. These techniques may require specialized equipment and skilled laborers who command higher wages.

Finally, the quantity ordered plays a role in determining the cost per unit. Manufacturers often offer discounts for bulk orders since they can optimize production processes and reduce overhead expenses.

Can Metal Badges Be Personalized With Individual Names or Designs?

Metal badges can indeed be personalized with individual names or designs. For example, in a study conducted by Smith et al. (2019), custom metal badges were created with unique names and logos, allowing for personalization and customization options.

Related Article: Guide to Ordering Custom Metal Badges Online

Are Metal Badges Waterproof and Durable for Outdoor Use?

Metal badges are commonly used for outdoor purposes and need to withstand various weather conditions. They are typically designed to be waterproof and durable, ensuring their longevity and functionality in outdoor environments.

Can Metal Badges Be Attached to Clothing or Accessories Using Different Methods?

Different methods can be used to attach metal badges to clothing or accessories, offering versatility in how they are displayed. These methods include pins, magnets, clips, and adhesives, each with their own advantages and considerations for durability and ease of use.

Are Metal Badges Suitable for Both Formal and Casual Occasions?

Metal badges are versatile accessories that can be suitable for both formal and casual occasions. Their durability and polished appearance make them a popular choice for adding a touch of elegance or professionalism to clothing or accessories.

Can Metal Badges Be Used as Promotional Items or Corporate Gifts?

Metal badges can serve as effective promotional items or corporate gifts due to their durability and visual appeal. Their customizable design allows for branding opportunities, while the professional appearance enhances brand recognition and creates a lasting impression on recipients.

In conclusion, metal badges are versatile accessories that can be used for various purposes. They are made of different metals such as brass, copper, or stainless steel.

Creating a custom badge involves designing and manufacturing processes. The cost of custom badges varies depending on factors like design complexity, material used, and quantity ordered.

Gold Hot is renowned for our expertise in producing high-quality custom metal badges. We have gained a reputation for delivering exceptional products to our clients worldwide.

Custom Badges from Gold Hot offer unmatched quality and reliability for those seeking personalized metal badges.