In the realm of durable signage, the selection of a custom stainless steel nameplate comes with a myriad of considerations that extend beyond mere aesthetic appeal. Key among these is the choice of stainless steel grade�?04 versus 316—each offering different levels of corrosion resistance suitable for varying environmental conditions. Furthermore, customization features such as texturing, engraving, and coating options not only contribute to the visual impact but also to the longevity of the nameplate. As we explore these elements, one must ask: how do these factors interplay to meet both functional needs and design aspirations, and what implications do they hold for overall sustainability and cost-effectiveness?

Stainless steel, renowned for its corrosion resistance and strength, is available in various grades that cater to distinct applications and environments. Understanding the chemical composition and material properties of these grades is pivotal for selecting the appropriate type of stainless steel for any specific use.

Each grade of stainless steel possesses a unique chemical makeup that determines its aptitude for resisting corrosion, withstanding high temperatures, and maintaining structural integrity under stress. For instance, Grade 304 stainless steel, which includes 18% chromium and 8% nickel, is widely recognized for its excellent formability and resistance to oxidation. This makes it an ideal choice for environments that require durability and frequent cleaning.

Moreover, the surface finishes and polishing techniques applied to stainless steel can significantly influence its performance and aesthetic appeal. A polished finish not only enhances the material's appearance but also increases its resistance to environmental factors by reducing the surface area available for corrosive elements to latch onto.

Therefore, precise control over the polishing process is essential to achieve both the desired look and the functional durability required in challenging conditions.

When designing a custom stainless steel nameplate, a variety of customization options are available to tailor the product to specific aesthetic and functional requirements. The power to personalize begins with font selection, where the choice can range from sleek, modern aesthetics to more classic, elegant scripts. This choice significantly influences the nameplate's readability and character.

Further customization is seen in the color options. While the quintessential silver sheen of stainless steel is popular, advancements in technology allow for a spectrum of colors through processes like powder coating or anodizing. This enables the nameplate to align with corporate branding or personal preference, enhancing its visual appeal.

Size customization is equally important. Whether you need a small nameplate for individual identification or a larger one for broader visibility, the dimensions can be adjusted to meet any specific requirement. This flexibility ensures that every nameplate serves its purpose effectively, whether mounted on office doors, machinery, or showcased at industrial facilities.

Lastly, finishing choices play a crucial role. Options such as brushed, polished, or matte finishes not only contribute to the nameplate's longevity but also affect how it interacts with light and environment, thus offering another layer of customization.

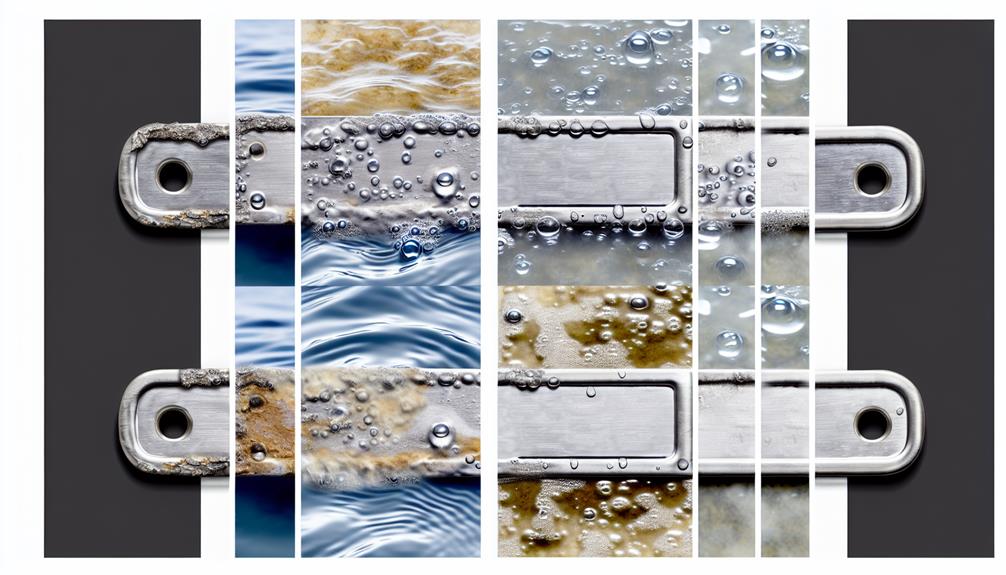

Beyond aesthetics and customization, the durability and corrosion resistance of stainless steel nameplates are fundamental to their performance in various environments. When selecting a nameplate for long-term use, especially in outdoor or harsh conditions, understanding the material composition is crucial. Stainless steel, renowned for its strength and resilience, contains chromium which forms a passive film of chromium oxide that blocks oxygen diffusion, enhancing rust prevention and ensuring longevity.

The specific grade of stainless steel used significantly influences its durability. For instance, Grades 304 and 316 stainless steel offer excellent resistance to a wide range of chemicals and atmospheric conditions. Grade 316, with its higher nickel and molybdenum content, is particularly adept at resisting saltwater corrosion, making it ideal for marine applications. This inherent robustness allows stakeholders to maintain control over the lifespan and performance of their nameplates, minimizing the need for replacements.

Furthermore, the finish of the stainless steel can also affect its corrosion resistance. Finishes like mirror and brushed provide not only distinct appearances but also additional protective layers against environmental factors. Choosing the right combination of grade and finish can empower users to optimize the durability and functionality of their stainless steel nameplates, aligning with their specific environmental challenges and aesthetic requirements.

Adhesive backing provides a reliable method for installing custom stainless steel nameplates, offering several options to suit different surface types and environmental conditions. Key to selecting the right adhesive is understanding adhesive strength and material compatibility. Adhesive strength must match the application's demands, ensuring the nameplate securely adheres through fluctuating temperatures, moisture, and mechanical stress.

Equally, the adhesive must be compatible with both the nameplate material and the surface to which it is being applied, preventing chemical reactions that could degrade either surface.

Selecting the appropriate adhesive involves considering whether the nameplate will be subjected to indoor or outdoor environments, as well as the presence of chemicals or extreme conditions. For indoor applications, a standard acrylic adhesive might suffice, providing a balance between strength and ease of use. For more demanding outdoor or industrial environments, epoxy-based adhesives offer enhanced durability and resistance to harsh conditions.

Additionally, understanding the surface energy of the substrate (the material of the mounting surface) is crucial. Low surface energy materials like polyethylene require adhesives with higher tack and shear strength to ensure a lasting bond, whereas high surface energy materials like metal allow for a wider range of adhesive options.

Screw attachment techniques offer a robust alternative for securing custom stainless steel nameplates, especially in environments where adhesive backing may not suffice. For those requiring a more permanent and secure mounting, screws provide excellent resistance to environmental factors such as moisture and temperature fluctuations. Furthermore, for industries like marine or construction, where conditions can be harsh, screw attachment ensures that nameplates remain firmly in place despite vibrations or physical impacts.

In addition to conventional screw fixing, rivet fastening is another highly reliable method. Rivets can handle significant mechanical stress, making them suitable for applications where nameplates must endure heavy usage or dynamic loads. This technique is particularly advantageous in settings where dismantling is not anticipated, providing a permanent solution that maintains the aesthetic integrity and readability of the nameplate.

Welding techniques also present a formidable option for attachment, especially when dealing with thicker nameplates or when additional security against removal is necessary. Welding, although requiring specialized equipment and expertise, results in a seamless and incredibly durable bond between the nameplate and its substrate. This method is ideal for environments where maximum security and minimal maintenance are paramount, ensuring that the nameplate remains an integral part of the installation without the risk of detachment.

Proper surface preparation is crucial for ensuring the secure attachment and longevity of custom stainless steel nameplates. Before initiating the installation, thorough polishing techniques should be employed to eliminate any surface imperfections. This not only enhances the aesthetic appeal but also prevents dirt or moisture from undermining the adhesive bonds.

Polishing should be followed by proper care to maintain the pristine surface, involving gentle cleaning agents and soft cloths to avoid scratches.

Additionally, rust prevention plays a pivotal role in surface preparation. Applying a protective coating can significantly extend the durability of the nameplate by shielding it from corrosive elements. This step is especially critical in environments prone to high humidity or chemical exposures. Ensuring that the stainless steel is completely dry and free from contaminants before this application is essential for optimal protection.

As a finishing touch, inspect the prepared surface meticulously for any residual debris or fingerprints. The final cleanliness guarantees that nothing interferes with the adhesive or mechanical fasteners used for mounting the nameplate.

To ensure the longevity and appearance of your custom stainless steel nameplate, proper maintenance is essential. Implementing regular cleaning routines helps maintain its pristine condition, while being aware of and mitigating corrosion risks is crucial to preserve the material's integrity.

Additionally, adopting long-term preservation strategies will protect the nameplate against environmental and mechanical wear over time.

Regular maintenance, including routine cleaning, significantly extends the lifespan and preserves the aesthetic appeal of stainless steel nameplates. By adopting effective cleaning techniques and polishing methods, owners can ensure their nameplates remain pristine and visually appealing.

Start by gently wiping the surface with a soft, damp cloth to remove any loose dirt or debris. For more stubborn residues, use a mild detergent diluted in warm water, applying it to the surface with a soft sponge or cloth.

To prevent fingerprints and smudges, which can detract from the appearance of stainless steel, consider using a specialized microfiber cloth. These cloths not only remove existing marks but also reduce the likelihood of future fingerprints. After cleaning, it's crucial to dry the nameplate thoroughly with another dry microfiber cloth to avoid water spots.

For enhancing shine and providing a protective layer, apply a light polish designed specifically for stainless steel. Use a clean cloth to apply the polish in a circular motion, then buff gently until the surface shines. This not only improves the nameplate's appearance but also forms a barrier against dirt and fingerprints, maintaining its immaculate condition over time.

Mitigating corrosion risks in stainless steel nameplates involves implementing specific care and maintenance strategies to protect against environmental factors that could degrade the material.

Understanding the chemistry of the stainless steel used and ensuring material compatibility with environmental conditions is crucial. For instance, Grade 304 stainless steel, while excellent for indoor applications, may not hold up as well in coastal areas where salt spray is prevalent, potentially necessitating a higher grade like 316.

To effectively control these risks, assess the specific environmental factors your nameplates will face. This includes considering air quality, exposure to chemicals, and the amount of moisture in the environment.

Regularly inspect your nameplates for signs of wear and corrosion. Early detection allows for timely intervention, preventing minor issues from escalating into significant damage.

Furthermore, use protective coatings that are compatible with the stainless steel grade to provide an additional barrier against corrosion. Choosing the right sealant or finish can dramatically increase the lifespan of the nameplate by reducing its direct exposure to corrosive elements.

Implementing a comprehensive maintenance strategy is essential for the long-term preservation of stainless steel nameplates. To safeguard their enduring quality and appearance, it is paramount to focus on both preservation techniques and judicious material selection from the outset. Choosing the correct grade of stainless steel, one that offers resistance to environmental challenges such as corrosion and abrasion, plays a critical role in the lifespan of these nameplates.

Routine cleaning should be performed with gentle, non-abrasive cleaners to avoid scratching the surface. Employ soft cloths and avoid chlorine-based solutions, which can compromise the structural integrity of the stainless steel. For outdoor applications, consider protective coatings that can shield the nameplate from harsh weather conditions and UV exposure.

Additionally, periodic inspections can help in early detection of potential issues, allowing for timely interventions that prevent deterioration. This proactive approach not only enhances the durability of the nameplates but also ensures they continue to reflect a professional and pristine image.

When evaluating the cost of custom stainless steel nameplates, it is essential to consider various supplier options to ensure competitive pricing and quality. A thorough cost comparison and deliberate supplier selection are critical steps in managing your budget while achieving the desired standards.

By soliciting multiple quotations, you can analyze not only the price differences but also understand the value each supplier brings in terms of material quality, fabrication precision, and delivery timelines.

It is advisable to look beyond the initial cost and assess the total cost of ownership, which includes factors such as durability, maintenance needs, and the longevity of the nameplates. Suppliers who offer seemingly low prices might compromise on stainless steel grade or finishing processes, which can affect the appearance and resilience of the nameplates over time.

To exert greater control over the outcome, prioritize suppliers with transparent pricing models and a proven track record of reliability and customer satisfaction. Engage in discussions with potential suppliers to clarify any concerns about their manufacturing processes or the materials used.

This proactive approach ensures that you are making an informed decision, securing a cost-effective yet high-quality solution tailored to your specific needs.

Yes, stainless steel nameplates can be recycled after use. Their recycling possibilities minimize environmental impact, offering sustainable disposal options and aligning with eco-friendly practices that empower users to control their ecological footprint effectively.

Stainless steel nameplates are highly suitable for marine environments due to their exceptional corrosion resistance, which significantly enhances their durability and lifespan, ensuring sustained performance and control in challenging conditions.

Stainless steel nameplates, akin to a steadfast lighthouse amidst stormy seas, do not disrupt electronic devices due to their non-ferrous nature, ensuring electronic compatibility alongside ample design options and customization opportunities for lasting durability.

Stainless steel nameplates are typically packaged using robust materials ensuring protection during shipping. Methods include foam or bubble wrap and sturdy boxes, with clear labeling to facilitate efficient and secure delivery to the destination.

Stainless steel nameplates typically include a warranty covering material durability and customization accuracy, ensuring customer satisfaction. Buyers often enjoy peace of mind with assured product longevity and fidelity to specified designs.

In conclusion, selecting a superior stainless steel nameplate necessitates a nuanced understanding of material grades, coupled with a keen consideration for customized design elements. The right choice balances aesthetic appeal with structural durability, ensuring resistance to environmental stresses.

Thoughtful consideration of installation and maintenance enhances longevity. Ultimately, by comparing costs and scrutinizing suppliers, one can secure a cost-effective and quality-assured solution that meets both functional needs and visual preferences in a demanding environment.

Elevate your brand or project with our specialized metal and non-metal nameplates. Gold Hot Industrial Co., Ltd. pioneers bespoke designs, catering to various industries. Whether for furniture labels, advertising, crafts, or more, our precision stamping and casting machines ensure top-quality products.

Contact us for a free quote for customizing your ideal custom stainless steel nameplate!